Farashin SPCCfarantin karfe

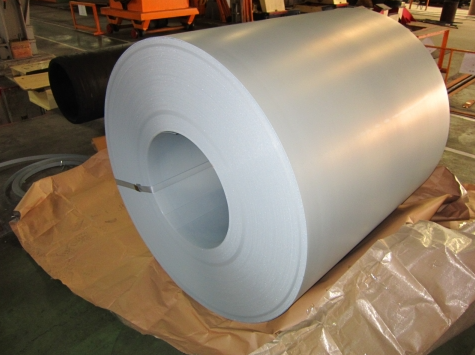

SPCC karfe farantin karfe nesanyi birgima carbon karfe farantinƙayyadaddun ƙayyadaddun ma'aunin masana'antu na Japan (jis g 3141).Cikakken sunansa shine "karfe farantin sanyi birgima ingancin kasuwanci", inda spcc ke wakiltar halaye da amfani da wannan farantin karfe: s yana wakiltar karfe., p yana nufin flat plate, c na nufin darajar kasuwanci, kuma c na ƙarshe yana nufin sarrafa birgima mai sanyi.Wannan farantin karfen farantin karfe ne mai ƙarancin carbon wanda galibi ana amfani da shi don yin sassa don sabbin firji, firji da aka rage ko kuma bel ɗin jigilar motoci na atomatik.Wannan farantin karfe yana da kyawawan abubuwan ƙirƙira da kaddarorin hatimi, kuma ana iya sarrafa su ta hanyar hatimin sanyi mai zurfi.Saboda ƙarancin abun ciki na carbon, yana da ƙayyadaddun kayan aikin injiniya amma yana da kyakkyawan filastik, yana mai da shi sauƙi da sauƙi don siffata zuwa girma dabam dabam.Kodayake farantin karfe spcc bai dace da aikace-aikacen da ke buƙatar ƙarfin ƙarfi ba, har yanzu ana amfani da shi sosai a masana'antu da yawa kamar kayan gida da motoci.A lokaci guda, wannan abu kuma yana da kyakkyawan juriya na lalata kuma ana amfani dashi sosai a lokuta tare da manyan buƙatu.

The surface jiyya na spcc karfe farantin za a iya yi ta hanyoyi da yawa.Ga wasu hanyoyin gama gari:

Tsabtace injina: Yi amfani da kayan aiki kamar goga na waya ko yashi don gogewa da kurkure saman don cire datti kamar tsatsa da mai.

Maganin sinadarai: yin amfani da acid, alkali ko sauran magungunan sinadarai don narkar da ko canza oxides ko wasu ƙazanta zuwa abubuwa masu tsabta don cimma manufar tsaftace farfajiya.

Jiyya na Electroplating: Ana yin platin ƙarfe a saman farantin karfe ta hanyar electrolysis don samar da Layer na kariya na karfe don inganta juriya da bayyanarsa.

Maganin shafawa: Fesa launuka daban-daban na fenti akan saman farantin karfe na spcc don kunna ayyukan lalata da ƙawa.

Hanyoyi daban-daban na jiyya na saman sun dace da bukatun masana'antu daban-daban.Zaɓin hanyar da ta dace don bi da farfajiyar farantin karfe na spcc bisa ga ainihin halin da ake ciki zai iya tsawanta rayuwar sabis kuma ya kula da kyawawan kayan aikin injiniya.

SECC farantin karfe

Cikakken sunan SECC shine Karfe, Electrolytic Zinc-coated, Cold Rolled Karfe Coil, wanda shine farantin karfe wanda aka sanya shi ta hanyar electrolytically bayan mirgina sanyi.Fuskar da aka yi amfani da ita ta hanyar electrolytically don samun ingantacciyar aikin rigakafin lalata da kyan gani.Yawancin lokaci ana amfani da shi don kera samfura tare da ƙarancin aikin hana lalata da buƙatun kayan ado, kamar su kwandon kayan gida, kayan kwalliyar kayan aiki, da sauransu.

Hanyar galvanizing SECC:

Hot tsoma Galvanized Coil: Hot- tsoma galvanizing ne anti-lalata magani da cewa samar da zinc Layer a saman karfe.Shi ne a nutsar da faranti na karfe ko sassa na ƙarfe cikin ruwa na tutiya narkakkar da aka riga aka rigaya zuwa yanayin da ya dace (yawanci digiri 450-480 ma'aunin celcius), kuma a samar da wani kauri da ƙaƙƙarfan murfin zinc-baƙin ƙarfe a saman sassan ƙarfe ta hanyar amsawa.Kare sassan karfe daga lalata.Idan aka kwatanta da electrolytic galvanizing, zafi tsoma galvanizing yana da mafi girman juriya na lalata da kuma tsawon rayuwar sabis, kuma yawanci ana amfani da shi don kera muhimman kayayyaki kamar manyan sassa na tsarin, jiragen ruwa, gadoji, da kayan aikin samar da wutar lantarki.

Hanyar galvanizing ta ci gaba: Ana ci gaba da nutsar da zanen gadon ƙarfe na birgima a cikin wankan plating mai ɗauke da narkar da zinc.

Hanyar galvanizing Plate: Ana nutsar da farantin karfe da aka yanke a cikin wanka mai ɗorewa, kuma za a sami zuriyar zinc bayan plating.

Hanyar Electroplating: electrochemical plating.Akwai maganin sulfate na zinc a cikin tanki na plating, tare da zinc a matsayin anode da farantin karfe na asali kamar cathode.

SPCC vs SECC

SECC galvanized karfe takardar da SPCC sanyi birgima karfe takardar ne biyu daban-daban kayan.Daga cikin su, SECC tana nufin zanen gadon ƙarfe na ƙarfe da aka yi birgima na electrolytically, yayin da SPCC shine daidaitaccen takardar takarda mai sanyi na duniya.

Babban bambance-bambancen su shine:

Kaddarorin jiki: SECC yana da murfin zinc kuma yana da mafi kyawun juriya na lalata;SPCC ba shi da Layer anti-lalata.Saboda haka, SECC ya fi SPCC dorewa kuma yana hana tsatsa da lalata.

Jiyya na saman: SECC ya sha electrolytic galvanizing da sauran hanyoyin jiyya, kuma yana da ƙayyadaddun kayan ado da kayan ado;yayin da SPCC ke amfani da tsarin mirgina sanyi ba tare da jiyya ba.

Amfani daban-daban: SECC galibi ana amfani da shi don kera sassa ko casings a cikin fagagen na'urorin lantarki, motoci, da na'urorin gida, yayin da SPCC ake amfani da su sosai a masana'antu kamar gini, masana'anta, da marufi.

A takaice dai, ko da yake duka biyun faranti ne mai sanyi-birgima dangane da abubuwan aiwatarwa, akwai bambance-bambance masu mahimmanci a cikin abubuwan da suke hana lalatawa, jiyya da amfani da su.Ya kamata a ƙayyade zaɓin farantin karfe na SECC ko SPCC bisa ƙayyadaddun yanayi, la'akari da dalilai daban-daban kamar amfani da samfurin da ake ƙerawa, yanayi da ainihin buƙatun, da zaɓin mafi dacewa kayan.

Lokacin aikawa: Nuwamba-06-2023